Child-resistant zipper bags, as the name suggests, are packaging designed to prevent accidental opening by children. According to incomplete statistics, tens of thousands of accidental poisonings involving children occur globally each year, particularly among those under three years old. Most incidents involve pharmaceutical products. Child-resistant packaging serves as the final line of defense for child food safety and is a crucial component of product safety. Consequently, child-safe packaging is gaining increasing attention today.

Child safety is the top priority for every family, yet many home environments harbor hidden dangers. For instance, children may accidentally open packaging for hazardous items like medications, cosmetics, or toxic substances, leading to accidental ingestion. To safeguard children, specialized packaging must incorporate child-proof features, significantly reducing the risk of accidental opening and ingestion.

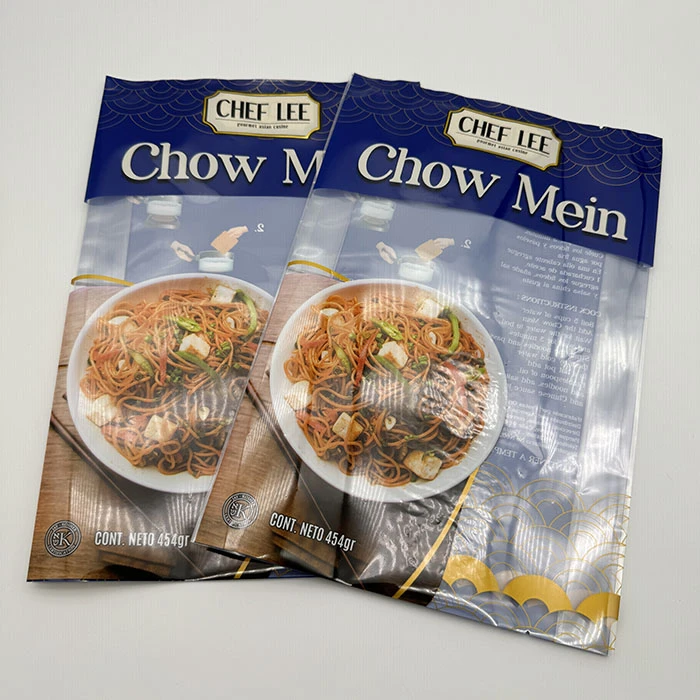

Our child-resistant packaging bags combine childproof functionality with product freshness preservation.

Child-resistant packaging bags are a popular choice for distributors of pharmaceuticals and other hazardous products for children. These bags are opaque, preventing curious children from seeing the contents, and like other barrier packaging bags, they offer superior barrier properties. Today's polyester film bags prevent children from opening them and allow for repeated opening and closing: they feature special child-resistant zippers that make them reusable.

Due to its chemical structure, polyester film helps extend the shelf life of both food and non-food products. As a freshness-preserving packaging material, polyester film excels at maintaining product integrity, making it widely adopted in food storage bags. It effectively blocks moisture and air, keeping products dry over extended periods. Its durability allows for long-term storage even in crowded pantries, while also withstanding bulk and individual transportation.

The zipper lock at the top of the packaging bag provides a seal to extend product shelf life and prevent contamination. Polyester film blocks ultraviolet rays, protecting products from degradation caused by UV exposure. Furthermore, the packaging material is made from non-toxic, harmless chemicals. These features help preserve product quality—particularly for pharmaceuticals—for as long as possible.