In current foil packaging bag design, many buyers no longer limit themselves to traditional structures like three-side sealed, four-side sealed, octagonal sealed, or back-sealed foil bags. Instead, they opt for specialized bag shapes. So, can aluminum foil material be used to make irregularly shaped foil packaging bags? The answer is definitely yes. Aluminum foil material possesses excellent plasticity, allowing it to be easily processed into packaging bags or containers of various shapes.

Composite aluminum foil bags are typically made by laminating two or more layers together, also known as laminated aluminum foil bags. They can be used for packaging in multiple industries such as food, electronics, and daily necessities. Examples include: PET/AL/PE (for general moisture-proof, light-blocking, vacuum-sealed packaging) PET/NY/AL/PE (for packaging requiring higher moisture resistance, light blocking, and vacuum sealing) PET/NY/AL/CPP (commonly used for food, ready-to-eat meals, and products requiring high-temperature retort processing)

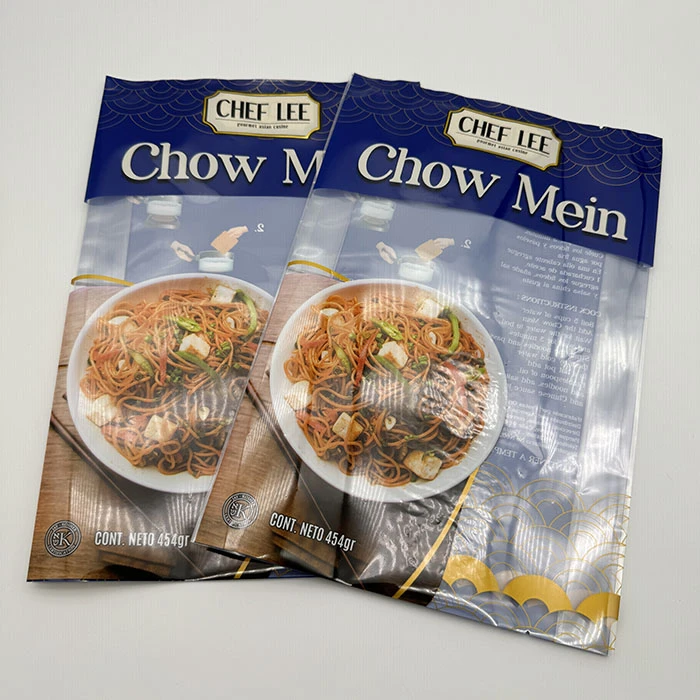

Composite foil bags offer multiple advantages including moisture resistance, oxygen barrier, waterproofing, and UV protection. Additionally, they effectively prevent oxidation, block aroma loss, and preserve food freshness and nutritional value, earning widespread adoption and acclaim. Shaping foil bags into custom forms enhances product appeal and captures consumer attention. Combined with exquisite printing, this elevates the product's market presence.